Our clients often wish to create production samples of new designs for brand evaluations, line trials, or consumer panels. Our Process Excellence team can perform unit or multi-cavity sampling to produce containers as needed.

In many cases, producers have run the same container, or a family of containers, for an extended period of time. Process drift, changes in material composition or preform supplier, and blow molder maturation can occur incrementally and add up to measurable waste and loss.

Our Process Excellence team can optimize existing container manufacturing, paying close attention to uptime, scrap reduction, high pressure air usage, and process discipline to bring meaningful cost savings and productivity.

Optimal Performance

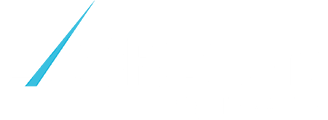

Base Clearance Mold Analysis

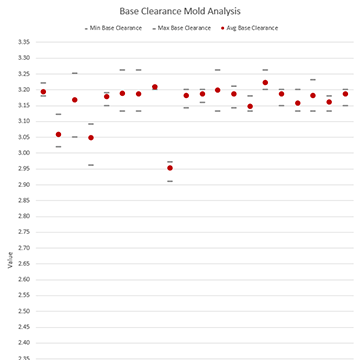

Shoulder Weight Mold Analysis

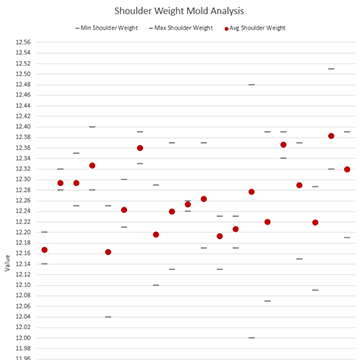

Volume Mold Analysis

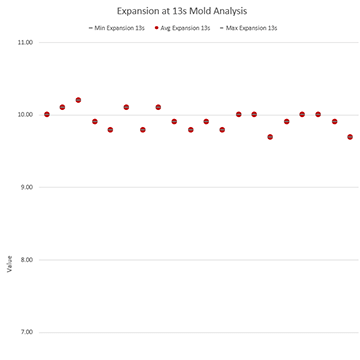

Expansion at 13s Mold Analysis

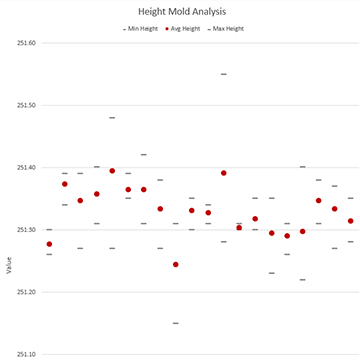

Height Mold Analysis

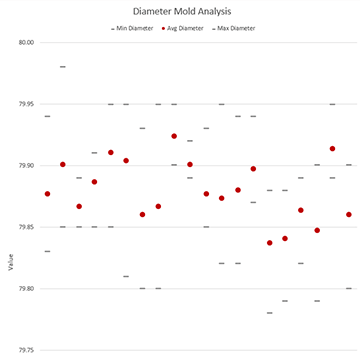

Diameter Mold Analysis

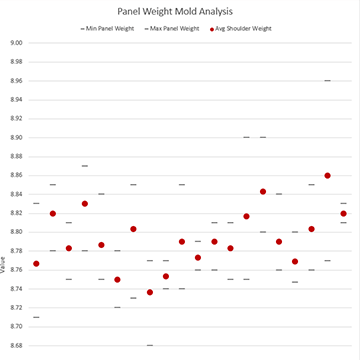

Panel Weight Mold Analysis

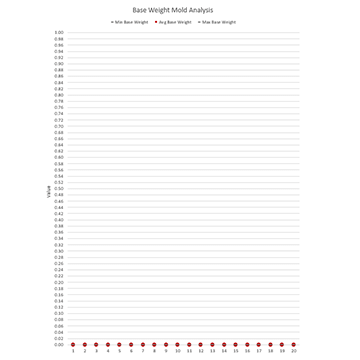

Base Weight Mold Analysis

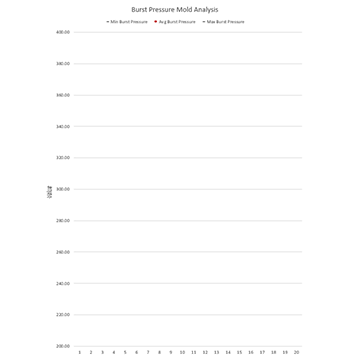

Burst Pressure Mold Analysis

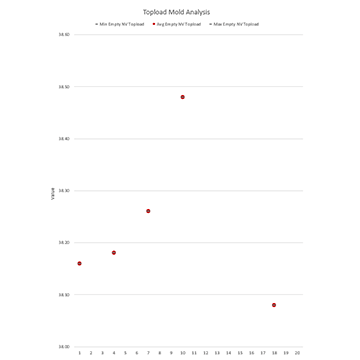

Topload Mold Analysis

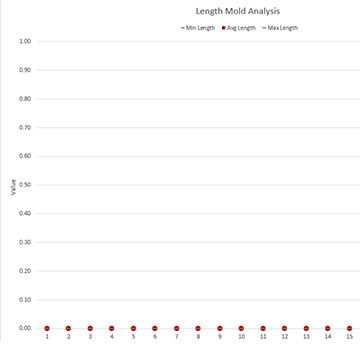

Length Mold Analysis

Width Mold Analysis